Beer me

June 15, 2010

[caption id="attachment_644" align="alignleft" width="300" caption="Empty bottles, waiting to be filled."][/caption]

[caption id="attachment_644" align="alignleft" width="300" caption="Empty bottles, waiting to be filled."][/caption]

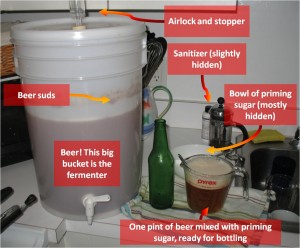

[caption id="attachment_625" align="alignleft" width="300" caption="Bottling setup."][/caption]

[caption id="attachment_625" align="alignleft" width="300" caption="Bottling setup."][/caption]

[caption id="attachment_645" align="alignleft" width="294" caption="Uncarbonated (yes, uncarbonated - all the bubbles are on the top) beer."][/caption]

[caption id="attachment_645" align="alignleft" width="294" caption="Uncarbonated (yes, uncarbonated - all the bubbles are on the top) beer."][/caption]

[caption id="attachment_647" align="alignleft" width="300" caption="The filled bottles."][/caption]

[caption id="attachment_647" align="alignleft" width="300" caption="The filled bottles."][/caption]

About this time last year, I became very interested in brewing my own beer. As far as I can tell, over the past few years home brewing has become increasingly popular (though it is possible it has always been popular, and I just hadn’t heard about it). At the time I was in one of the most important beer cities in America, so I headed to a local craft brewing store to pick up the necessary equipment.

About $200 later, I was on my way to making my first beer, an IPA - I really like their bitterness and hoppiness.

After much frustration, I ended up with about a dozen bottles of OK beer - and a dozen more that for some reason didn’t carbonate at all; I have some ideas as to why that might be.

I often find that the first time I do something it’s extremely difficult, annoying, and expensive, but once that’s out of the way it’s much easier. And so I was looking forward to brewing a second batch of beer.

So, about two weeks ago, I bought a wheat beer kit from Amazon, took down my brewing equipment, and started a new brewing process. After letting the beer ferment for about a week, it was time to bottle.

You can see my bottling setup in the second picture.

The big white bucket is where the fermented beer is. Basically, to make beer, you add water, malted hops, sugar, and yeast to this bucket. The yeast turns the sugar into alcohol, and that all happens within this bucket. I’ll talk in more detail about this process in a future post, but this is a good initial simplification to use in understanding the process.

You’ll also notice an airlock, and a bottle of sanitizer that I did a bad job of getting in the picture. Both of these things are important as part of the sanitizing process while the beer is being made. Basically, all equipment is soaked in a solution of water and sanitizer before being brought into the actual beermaking process. This makes it easier for the yeast to grow by eliminating competition from other microorganisms.

The airlock on the top of the fermenter allows air to escape during the fermentation process, without letting more (contaminated) air in.

What else? You’ll notice I have a bowl of “priming sugar”. This is added to the bottles just before they are sealed. The yeast will convert this priming sugar into carbon dioxide. As I briefly mentioned above, this process didn’t go so well for me last time, which resulted in flat beer.

When the beer has completed its initial fermentation, it’s drawn out of the fermenter, and into the measuring cup where I add the priming sugar. It’s then poured into bottles, and the bottles are capped using a special hand-powered machine that makes a tight seal between the bottlecap and the bottle.

Here’s a great site that summarizes the process and gives much more information as well. I intend to refer to it in the future: http://www.howtobrew.com/intro.html.